Review: Miyabi 613 hunting knife

Publication date: 7 July 2012. Last modified 07-Jul-2012.

When I discovered I could use Amazon affiliate referral money to buy this...

...I obviously had to do it.

This knife has many sensible and practical qualities.

It makes a pretty good machete, for instance. With a little extra sharpening, it worked OK as a bread knife. I think it'd make an excellent hunting, camping or survival knife.

You could, um, use it to open a champagne bottle.

Or sharpen pencils. Carefully.

Any attempt on my part to get you to believe that I bought this thing for some practical reason is, of course, doomed to failure. I bought it because it is a big eff-off shiny knife that is large enough to make a satisfying swishing sound when you pull it out of the scabbard.

It is large enough, in fact, that I'm pretty sure Crocodile Dundee would be happy to acknowledge that this is, in fact, a knife.

And it provides me with an excuse to rabbit on interminably, on this page, about knives and stabbing weapons, which is something I seldom get to do except while making constant eye contact with a fellow traveller on a long, long bus trip.

And, of course, it kind of looks like a katana. And Katanas Are Just Better.

Well, actually they're not. Even in the subcategory of Japanese swords that contains those that qualify as katanas, there's an enormous amount of variation in size, quality and metallurgy, and quite a bit of variation in shape, too. There's no clear way in which katanas in general are superior to various other swords from other countries.

But you don't have to believe Kill Bill was a documentary to harbour an atavistic desire to own a slightly curved Japanese man-sticker. An abbreviated katana, like this knife, is a lot more affordable than a full-sized one, and a lot less likely to maim its clumsy owner or a hapless passer-by.

So, OK, for me and probably for almost everybody else who buys one, this knife is essentially a toy.

But it's a really cool toy.

Facts and figures

According to the seller,

Hartmann & Haug

in Germany, this is a "HUGE

HUNTING KNIFE

Miyabi 613 BY Ichiago, Japan".

It cost me $US49 plus delivery. That delivery, even to me here in Australia, was surprisingly cheap, so the grand total price was only $US56.49. As I write this, that's about $55.50 Australian, €46, or £36.50.

(International delivery can be tricky, for Amazon purchases other than books and DVDs. You can

buy

almost

anything

on Amazon, but many items can only be delivered within the USA. Nowadays at least some Amazon listings tell

us foreigners that a given item can't be delivered to us, but we still often need to go half-way through the checkout

process before we find out. This leads to ridiculous strategies like adding ten copies of the one item you want from

ten different Amazon vendors, and hoping that at least one of them turns out to work, after which you manually delete

any other surviving sellers before finishing the order. This knife is not like that. If they'll send it to Australia,

I presume they'll send it to most other countries.)

I think the "HUGE" in the Amazon listing for this knife, if not its capitalisation, is justified.

The Miyabi 613's overall length is about 425mm (16.7 inches). The blade's about 291mm (11.5 inches) long, with an edge about 275mm (10.8 inches) long. The handle's 128mm (5 inches), and there's a small but chunky 4.5mm (0.18 inch) thick unornamented oval steel guard, or "tsuba"...

...in between.

(The blade, handle and tsuba measurements don't quite add up to the overall-length one because of the curvature of the blade. The blade is about 291mm long if measured along its spine, or a bit longer if you measure diagonally from the start of the edge side of the ricasso to the tip.)

The only accessory the Miyabi 613 comes with is a tough black nylon scabbard with a belt loop, and a hook-and-loop ("Velcro") strap at the top that goes around the knife's handle so it won't hop out of the scabbard if you jump around.

Without the scabbard, the knife weighs only about 330 grams (11.6 ounces). This despite the blade being quite hefty, as is common in blades of this pattern; the spine is nearly 5mm (0.2 inches) thick.

The spine of the blade is polished, but the un-ground sides still have black "forge scale" on them. This is a popular technique to make a cheaply-made knife look handmade and expensive, but it doesn't do any harm.

Technically, I think this knife's blade length, of about one shaku - the "Japanese foot" - qualifies it as a large "tanto". But it's possible the heftiness of the blade means it's better described as a small "shoto", or short sword.

If you're a Bushido-obsessed Japanophile, though, you probably don't want this thing. It's about as authentically Japanese as Outback Steakhouse is authentically Australian.

The details

This knife may actually have been made in Japan, but I wouldn't bet my life on it. There's an etching on the blade that says "Izumi Ichiago, Seki Japan", but searching for that doesn't seem to turn up anything except for umpteen dealers selling sundry other inexpensive knives with the same etching on the blade.

(If you search for "miyabi knife"

on eBay

or Amazon,

you'll find kitchen knives under that name from the cutlery megabrand

Henckels. Those knives are unrelated to this HUGE HUNTING

ET CETERA; "Miyabi" is just a Japanese word for a certain kind of refined

aesthetics, with which this knife may or may not comply.)

This knife is also not made from fancy steel, or elaborately heat-treated or polished. It's just a chunk of what the listing calls "finest carbon steel", with an edge on it.

The modern world is full of inexpensive objects made from what'd qualify as "finest carbon steel" from the point of view of people who lived before guns were more popular than swords. If you went to a junkyard and grabbed some truck leaf springs, then hopped in your time machine and went back 500 years, you could pretty much name your price for that steel.

(You can buy katanas made from spring steel today. They're

pretty cheap

- when compared with other actual usable swords, as opposed to purely decorative "wall hangers" - and

quite good, and very

resilient. A samurai would probably be very interested in

a sword like this which, OK, maybe doesn't hold an edge quite as well as his usual blade, but which is virtually unbreakable.)

So given the "finest carbon steel" description, I figured this knife was just made from some spring-or-higher grade of junkyard steel, like my Roman Army knife. Which would be fine, and useful. Carbon-steel knives are cheap and hold an edge well, and if you clean the blade after use and don't spend a lot of time camping in the rain or fighting in a trench, rust is unlikely to be a problem.

I'm pretty sure this knife isn't actually made from carbon steel, though. I don't know what it's made from, actually, but it appears to be stainless.

A magnet sticks to the blade (and the little crossguard tsuba, for that matter), which means the metal can't be the austenitic stainless that's used for kitchen sinks, marine fittings and various other applications where toughness and maximum corrosion resistance are important, but sharpness is irrelevant. Martensitic stainless, however, is magnetic, and numerous modern knives (and forks, and spoons) are made of one or another martensitic stainless alloy.

A simple and pretty reliable way to tell the difference between carbon steel and martensitic stainless is to make up a solution of copper sulfate ("bluestone" from the garden centre will work), and put a drop on the metal. If it's stainless steel nothing will happen, but if it's carbon steel then, in seconds, some of the more-reactive iron will go into solution, some of the less-reactive copper will come out, and you'll get a little dot of super-thin copper plating on the surface of your steel.

I could show you what happened when I tried this on the Miyabi 613 HUGE HUNTING ET CETERA, but all it looked like was a drop of blue liquid on a metal surface. No reaction, no plating, therefore probably no "finest carbon steel".

There are some carbon steels that don't respond to the basic copper sulfate test (technically they're "alloy steels", not carbon steels, because by definition the only components of carbon steel are iron and carbon; add more than trace amounts of anything else and it's an alloy steel). But these particular hoofbeats almost always identify a stainless-steel horse, not an exotic-carbon-steel zebra. Nobody's making large fifty-dollar knives out of exotic alloys.

(Oh, and if you're wondering: The black forge scale on the un-ground sides of the blade also doesn't mean it's not stainless. Forge scale on stainless may have a different composition from similar-looking scale on carbon steel - stainless scale may, for instance, include some ultra-hard chromium oxide, which may actually be desirable. But it'll look much the same either way.)

As a general rule, stainless steels - which actually can still rust, but are much less prone to it - are softer than carbon steel, so they're easier to sharpen but don't hold an edge as well. Today, though, there are fancy low-chromium high-carbon stainless steels that cost a lot more than carbon steel, but stay sharp at least as long. And even boring old 440 stainless is, if you can get past the chatter of enthusiasts who spend far more time sharpening knives than they do using them, a perfectly practical knife material. Not so much for swords, though. There are lots of decorative wall-hanger swords made from 440 stainless, but the longer the blade, the more the bendiness of 440 becomes a problem.

It doesn't really matter what steel this thing's made from, of course, as long as it has a good edge and stays sharp when you use it. This too doesn't matter to people like me who buy a thing like this purely as a toy, but this is meant to be a hunting and/or camping and/or survival kind of knife. So it should take an edge, keep that edge reasonably well, and tolerate abuse.

Which brings us to...

Sharpening

If you think people get agitated about which sport team's the best, or what brand of car, or what computer operating system, you should see knife and sword enthusiasts arguing about sharpening.

"Look! This supposedly professional knife-sharpening dude is using a dry sanding belt, and it's running fast enough to strike sparks off the damn blade! He's ruining the temper!" (But apparently his professional-chef clients are all too dumb to notice their expensive German knives are now all, according to this complainant, wrecked.)

"Well, I suppose you can use an angle guide if you think you need to... you can also drink wine cooler with a little pink umbrella in it, and sit down to pee your girl-drinks out again. Who am I to judge?" (It is pretty much physically impossible to grind a truly flat bevel on a knife, or a chisel or plane blade, without some sort of mechanical assistance to hold the blade at the right angle. If you are not a humanoid robot or professional togishi, you will need mechanical help to grind a perfect flat bevel.)

"Waterstones!" "Oilstones!" "Waterstones!" "Oilstones!" "Wabbit season!" "Duck season!" (Different kinds of sharpening stone should be used with different kinds of liquid to float metal particles out of pores in the stone, and/or to help create an abrasive slurry. Not all "stones", especially modern synthetic ones, necessarily need to be used with any liquid at all. You certainly don't need to agonise over exactly what grade of oil to use; the stuff's not there to lubricate anything, since friction and abrasion is the whole point of the exercise. Samurai protected their swords from rust with clove-scented mineral oil, creating fetishisation of this particular substance - but the cloves were only in there so the mighty warrior wouldn't mistake his sword oil for his frying-pan oil and absent-mindedly loosen his bowels.)

"Translucent Arkansas oilstone that comes in a cedar box!" "Belgian coticule matured in a Roman ruin for two millennia!" "Twenty-thousand-grit synthetic Japanese waterstone that comes packed in the bloom from the cheeks of ten thousand geisha and somehow manages to cost even more than the natural stones!" (Oh, for Pete's sake.)

(Full disclosure: I own a translucent Arkansas oilstone in a cedar box, which coincidentally has

my name on it.

It smells lovely.)

As my contribution to these religious issues, here's what I reckon you need to do a truly good job at sharpening any everyday blade, including this Miyabi 613 HUGE HUNTING ET CETERA.

1: A big cheap coarse-on-one-side, very-coarse-on-the-other aluminium-oxide stone. Use this, with oil or water or nothing, for putting an edge on hopelessly blunt blades and on things where a fine edge is unnecessary, like machetes and lawnmower blades.

When I say cheap, I mean cheap. I most recently paid $AU2.50 each for a couple of 20cm (eight-inch) stones. This was an unusually good deal, but you should not contemplate spending more than ten bucks unless the stone is the size of a telephone directory.

2: A "diamond card" of some sort. These modern synthetic "stones" are pieces of steel impregnated with industrial diamonds, often with a pattern of holes for metal particles to drop into. They can be used with oil or water or nothing (if the third, the abrasive will get "loaded" with metal particles over time, and need an occasional wash and perhaps a bit of a scrub with a wire brush).

Dirt cheap discount-store diamond cards are OK, though I suspect the very cheapest ones don't have much diamond in them. (Or any. They could be loaded with emery or something for all I know.) Very cheap diamond cards may also have a very thin layer of diamond impregnation over diamond-less metal, and therefore wear out surprisingly quickly. Quality diamond cards should last approximately forever unless you sharpen things for a living.

I like DMT's diamond sharpeners. You can find them

here on Amazon

or

here on eBay. Get one of their double-sided folding

sharpeners (they fold like a butterfly knife!) with

blue "coarse" grit on one side and red "fine" on the other, and you're in business. (Note that DMT's idea of "coarse"

is similar to most people's idea of "fine".)

3: A ceramic "crock stick", that looks like a kitchen honing steel except the rod is made of smooth, hard ceramic, usually white. Even a "coarse" crock stick is rather fine compared with most sharpening stones, and the very small contact point between a cylindrical sharpener and a straight blade means that this sort of sharpener removes minuscule amounts of material. But it does actually remove material and so truly sharpen a knife, as opposed to honing steels that aren't meant to remove any material at all, only straighten the edge.

If you search for "ceramic sharpeners"

on eBay or

on Amazon,

the lowest-priced items will be a mixture of unmounted plain ceramic sticks without even a handle (which work well

enough if you're not clumsy, but I'd stick a chisel handle on them if I were you...), and plastic preset-angle sharpeners

with little crossed ceramic and/or carbide rods in them.

Those pre-set sharpeners are fairly safe for even klutzy people to use, and can work pretty well, provided the knife you're pulling through them has an edge bevel angle close to that of the fixed sticks. If the edge of the knife doesn't match the pre-set bevel, the sharpener will try to grind it to its one set angle anyway. This will take a long, long time and eventually give a sharper but more fragile edge if the knife's bevel is more obtuse than the pre-set angle. If the knife's bevel is more acute than the pre-set angle, the sharpener will work very quickly but make the knife blunter than when it was new.

(The dirt-cheap end of the knife-sharpener market also includes little rolling doodads like this, which actually may put a usable edge on many knives. Whenever someone uses one of those things on a knife that cost more than $5, though, it creates a sensation in people who know how to sharpen knives properly not unlike the sensation felt by Obi-Wan Kenobi when Alderaan was destroyed.)

4: A honing steel, if you must. A couple of strokes on the ceramic stick should work just as well as several on a steel, though. The ceramic sticks remove so little material that they have no perceptible effect, good or bad, on a knife that isn't already pretty sharp.

(Honing steels are known to some professional knife-users, like butchers and trawler crew, as "whiffling sticks". "Whiffling" means "doing something other than the work you're meant to be doing".)

You can now get honing steels impregnated with diamond like the diamond cards, which cost more but

work better than a crock stick. (DMT have

diamond "steels"

too.)

Note, however, that "work better" means "remove metal faster", which is not necessarily a good thing when you're learning. While learning, I suggest spending much more money on nice diamond sharpeners than you do on your actual knives. Practice on dollar-store knives, most of which can become perfectly serviceable kitchen tools once you learn to put an edge on them properly.

All of the above is just what I would do, though, and I'm hardly an expert. In olden tymes, I might be as much as a quarter of the way through my sharpening apprenticeship by now. Hand-sharpening is something you have to do by feel, and I now can often feel when I'm doing it right. And I almost always leave a knife better than I found it. Eventually.

Feel free to try some completely different system if you like, though. There is, for instance, the "scary sharp" technique, which was invented for sharpening woodworking tools with angle-guide jigs, but is perfectly applicable to knives too. "Scary sharp" doesn't use any kind of actual stone, just wet-and-dry abrasive paper stuck on plate glass to keep it flat. It's inexpensive and works just fine, and the huge area of the sandpaper "stone" makes it easier to consistently sharpen even quite large blades.

The edge of the Miyabi 613 HUGE HUNTING ET CETERA, as it came from the factory, was pretty sharp. I improved it a little more with a ceramic stick, but it was perfectly usable out of the box. Cheap knives are not always like this; discount-store/eBay bargains usually have at least some usable cutting edge, but it's common for the hastily-ground edge to not go all the way to the tip of the blade, and sometimes you'll get one that's blunt from tip to tail.

Authenticity, or lack thereof

The 330-gram weight of the HUGE HUNTING ET CETERA puts it roughly on par with Japanese swords (which are not all katanas) in weight-per-size. An unremarkable katana would have a blade about 2.5 times the length of this knife blade, and a handle about twice as long, and would probably still weigh significantly less than a kilogram.

(Swords, in general, typically weigh a lot less than many people think. If you ignore decorative or ceremonial swords, which are the historical equivalent of the modern stainless-steel wall-hanger, even quite large swords and heavy Roman-style shortswords seldom exceeded 1.5 kilograms {3.3 pounds}. Full-sized swords weighing less than one kilogram {2.2 pounds} were common. Even the very biggest two-handed swords, which were extremely rare and used more like polearms than like normal swords, weighed well under five kilograms. Weight is really important for something you intend to be waving around vigorously for a whole, lengthy battle. Even blunt weapons that depended on momentum for their effectiveness, like maces, were surprisingly light. The only reason to take a ten-kilo melee weapon into battle is if it keeps your enemies 25 feet away.)

Why, you might at this point wonder, did I a thousand or so paragraphs above this say that this blade is as authentically Japanese as Outback Steakhouse is authentically Australian, or chicken tikka masala is authentically Indian?

Well, apart from the stainless-steel thing, it's hollow-ground.

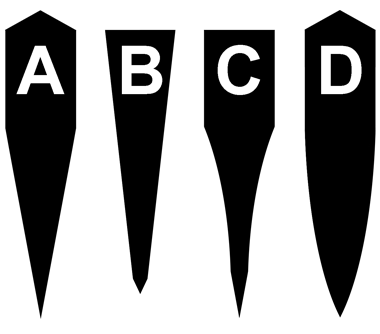

Traditional Japanese blades are usually flat-ground, with a cross-section that has several facets.

There are quite a lot of Japanese blade plans and cross-sections. I think the most common traditional Japanese sword grind, though, has a cross-section much like that shown in "A". With the spine of the blade, opposite the cutting edge, upwards, the spine comes to a blunt ridge, there's then a section where the sides are parallel or widen, and then there's one big acute bevel all the way down to the edge.

This sort of blade cuts very well, but its thin edge is fragile, even if the blade is made with all the fancy pattern-welding stuff that gives the better kind of katana-pattern swords an edge made from hard steel, with softer but tougher metal for the sides and back of the blade.

A blade with this sort of cross-section is troublesome to sharpen, because to do it properly you have to abrade the entire bevel, which extends half-way across the width of the blade (some blades have a flat bevel over their entire width). You can sharpen a blade like this quickly by just grinding a less acute "secondary bevel" onto the very edge; that's what the abovementioned little crossed-sticks sharpeners do to blades with a more acute angle than that of the sticks. But if you do that to an actual katana, even a crappy one from the end of the Second World War, Japanese ancestor-spirits will manifest and stare at you in that glowering Kurosawan way until you take up your dishonoured blade and use it to end your worthless life.

For this reason, and for the sake of durability, most single-edged blades have a profile more like "B" above. There's an acute primary bevel that takes up some or most of the width of the blade, and then a deliberately-ground, more obtuse secondary bevel that forms the actual cutting edge. To sharpen this blade, you only need to abrade the little secondary bevel, but the more you sharpen it, the more the secondary bevel will move up into thicker and thicker parts of the blade.

(Old, well-used, frequently-sharpened knives always end up looking like some kind of prison shiv, because hundreds and hundreds of sharpenings have worn away well over half of the original blade.)

This HUGE HUNTING ET CETERA knife's blade cross-section is like "C" above, with a parallel section up near the spine not unlike that of the authentic A-pattern blade, and a thin, acute secondary bevel...

...forming the cutting edge, and a hollow grind in between.

Hollow grinds are popular these days - many "B"-type blades today have a hollow-ground central section instead of a flat primary bevel - because automated machinery, or a knifemaker with a good-sized grinding wheel, can make them very easily. A hollow grind gives you a knife that slices well, is reasonably tough, and can be sharpened as easily as a "B"-type blade that has the same secondary bevel angle. It's really difficult to make a hollow grind if you don't have a grinding wheel of some kind; if you grind blades on a wheel, though, it's almost impossible to not make a hollow grind.

Some hollow-ground blades have no secondary bevel; the two hollow sides just come together almost asymptotically to create a fantastically thin, sharp and fragile edge. This is how most modern machine-made straight razors are ground, and they're almost foil at the edge. Push gently (and gingerly) on the side of a straight razor's edge and you can clearly see the metal flex.

This sort of edge is only useful for tasks like shaving and surgery, though, mainly because it's extremely easy to damage. Blades like this also need to have much greater thickness at the blade spine, because without a sturdy spine the blade will have more in common with a 0.1mm feeler gauge than a knife. For this reason, straight razors don't actually slice thick materials, including human flesh, very well. (He who brings a straight razor to a knife fight is either very good, or very crazy. Ebay is full of cheerful Chinese people selling extremely inexpensive straight razors which must be purpose-built for knife-fighting, because they sure as hell aren't any use for shaving.)

"D" in the picture is another blade cross-section found in some Japanese knives and swords; it's convex grind, the opposite of the hollow grind.

A convex grind is a bugger to make evenly by hand as the primary grind on a large blade, but it can combine good cutting ability with strength. For this reason, axes are often convex-ground. The convex grind can go all the way to the edge like "D", or it can have a small secondary flat or convex bevel, which may or may not have been put there on purpose. If you freehand-sharpen any knife whose edge is a secondary bevel (which is to say, almost all knives), you're probably going to create a convex bevel without even trying.

(This is why people use sharpening jigs when sharpening any blade that absolutely must not, for whatever reason, have a convex bevel. A convex bevel is unlikely to do much harm to the cutting ability of a tool, though. If you've got a blunt chisel or plane and don't have a sharpening jig, sharpening the tool freehand probably will make the edge convex, but probably won't ruin it.)

There's nothing wrong with a hollow grind, and many very old knives have it; once someone invents the spinning grindstone, hollow grinds immediately result. But it's not "authentic", for something that's trying to look katana-ish.

The HUGE HUNTING Miyabi 613 ET CETERA also lacks the traditional "kissaki" tip of a classic katana-pattern blade, with its clear and distinctive "yokote" line where the relatively thick blade starts to taper to the thin, stabby point. This knife's tip actually tapers a bit unevenly on the two sides (another sign that this is a cheap knife), with the edge bevel staying the same width right to the tip. The tip is thus a slightly off-centre point, not quite as skinny and stab-tacular as a kissaki.

This makes the point sturdier, though, and does not I think greatly inhibit the blade's ability to alter the topology of anybody to whom you vigorously introduce it. The lack of a kissaki also doesn't, by itself, disqualify a blade as traditionally Japanese; many smaller Japanese blades were kissaki-less, as were many blades, possibly still qualifying as katana by size, that were re-ground from a broken longer blade. (Some naginata, curved-blade Japanese polearms, were also made from damaged sword blades.)

Fittings

The handle of the HUGE HUNTING ET CETERA is matte-finish wood, shirasaya-style. Shirasaya sword fittings are plain wood for handle and scabbard, maybe with a plain tsuba as well, but probably not. These simple, inexpensive fittings were created to make it easy to store and handle blades that weren't currently being used. Recently shirasaya fittings have appeared in various movies and comics, though, so they've become fashionable and now show up as "working" sword fittings. This has also created the peculiar phenomenon of shirasaya scabbards and handles with decorative wood finishes, which is sort of like putting a spinner hubcap on a space-saver spare wheel.

Shirasaya fittings are not practical for a working knife, though, and they're especially impractical for a weapon. Plain smooth wood isn't grippy enough for use as a rough-treatment handle, and a cut-and-thrust sword without even a small crossguard is an open invitation for an opponent's weapon to slide down yours and cut your hand off, or for your sweaty hands to slide up the handle and onto the blade.

The Miyabi 613's handle mounting is moderately authentic to Japanese practice, though. There are two holes in the tang and handle (Japanese sword blades usually have only one), and there's a steel pin through each hole to retain the blade (traditional swords use bamboo pins). The pins don't quite sit flush with the surface of the handle, and the handle's unfortunately also glued onto the tang, so it'd be hard to swap the slippery wooden handle for a different, prettier and/or grippier, one without destroying the original handle.

(There's nothing wrong with attaching a handle to a blade with glue, as long as there's also at least one pin. Cheap knives often use nothing but glue, and don't have much of a tang either; this is barely acceptable for a butter knife, bad practice for a hunting knife, and a disaster waiting to happen for a sword.)

You could easily enough do some sort of knurling job on the handle for better grip, or braid something around it in one way or another, possibly retaining the braid with another hole through the wooden handle, past the end of the tang. Or you could just stick some friction tape on it or, for marginally greater verisimilitude, glue some of the rayskin used on traditional Japanese handles to it.

(You really can get just about anything on eBay, can't you?)

Personally, I got some funny-smelling sporting grip tape and tightly wrapped that onto the handle, starting from a bit of double-sided tape to encourage the grip tape to stay put, since this sort of grip tape sticks to itself very well if you wrap it tightly, but doesn't stick to wood particularly well.

This worked nicely, and effected a surprising transformation of the implement's appearance from "toy for boys" to "found near the third group of victims".

The Miyabi 613's tang is about two-thirds as long as the handle, which is plenty. Short, skinny or completely absent tangs are common in crappy and/or merely decorative knives; the classic example is the huge Rambo "survival" knife with a hollow handle containing fishing gear and matches and stuff, and with a blade that has almost no tang at all, and is just glued onto said handle. At the first sign of rough treatment, the blade and the handle part company.

(When this sort of knife is done properly, the blade and the hollow handle are one single piece of steel. Global kitchen knives are like this, too; the blade flows into the handle, which is hollow and, allegedly, filled with sand to balance the knife. Normal Western kitchen knives usually have a "full tang" that makes up the whole centre of the handle, with "scales" or "slabs" attached on either side of the tang to give you something to hold onto besides a steel stick. Traditional Japanese kitchen knives have cylindrical handles, with a tang of similar proportions to the Western versions hidden inside.)

Usefulness

After all this blather about steel and sharpening and blade cross-sections, you might wonder whether I have at any point actually tried doing something with this knife, besides stroking it with a faraway look in my eye and cuddling up to it at night.

I haven't gone camping with the Miyabi 613, but I did channel my inner George W. Bush and clear some brush in the yard.

Providence has favoured our front and back yards with a quantity of well-established blackberry plants. Blackberry isn't the easiest target for brush-chopping, on account of how you have to keep calculating where all those damn thorns are going to go when you start whacking branches. But the plant's obnoxiousness does make murdering it more satisfying.

I'm not particularly strong, and my brush-cutting talent is chiefly notable for its absence, but the HUGE HUNTING ET CETERA still made it easy for me to cut diagonally through 1.5cm (0.6 inch) green blackberry canes. Then I mis-used the knife more cruelly by using it to hack through dry branches of a small fallen tree, diameter from 25 to 30mm (about an inch to 1.2 inches). It took a bit of chopping to do this, and made clear to me that I needed a better grip on the knife's handle (I hadn't put the tape wrap on it yet), but the limiting factor was my own minimal strength and stamina, not the knife.

Afterwards, only a couple of spots toward the tip of the blade were noticeably blunter than they were when I started, and the whole edge was still quite sharp enough to smoothly slice paper. I ran out of blackberry after a while, but the knife stayed more than sharp enough to keep using for considerably longer. Whatever steel this thing is actually made of, it's not rubbish.

I was surprised how well the HUGE HUNTING ET CETERA compared with my unremarkable Made-In-China machete for these jobs. The machete weighs about 400 grams (14 ounces), about 20% more than the knife, and it's a total of 57 centimetres (22.4 inches) in length, giving it about half again as much blade length as the knife. I've put about as good an edge on the machete as is possible - you can put a razor edge on one of these simple slabs of mild steel if you want to, but it'll disappear as soon as you start cutting things with it. Many people let machetes and hatchets get so blunt that they cut about as well as a yardstick. But this properly sharpened machete seemed to cut brush no better than the Miyabi 613.

If you're actually hacking your way through a jungle then a longer blade is worth having, and more blade length

also lets you stay further away from thorny plants like blackberry. But if you're cutting kindling, or shelter or

fishing-rod components, the HUGE HUNTING ET CETERA works just fine. A purpose-made hunting and survival tool like

the famous Woodman's Pal would be even better, and

the basic Pal isn't very

expensive either, but it weighs twice as much as the Miyabi 613, and you can't stab anybody anything

with it.

Oh, and as I mentioned at the top of this review, the HUGE HUNTING ET CETERA does also work as a somewhat clumsy and ridiculous bread knife. Any good chef's knife should work as a bread knife, too; if you can't cleanly slice bread with it, it's not sharp enough.

Overall

I wasn't anticipating writing anything about this knife when I bought it; I certainly wasn't anticipating writing anything like this much. But this knife turned out to be a surprisingly solid product for the money, as well as providing an opportunity for me to ramble on endlessly, and it deserves to be more famous. I bought it as a toy and probably won't actually use it for much, but if you're in the market for a solid, good-sized fixed-blade camping/survival knife and would like something a bit different, the Miyabi 613 is well worth considering.

Whatever steel it's made from is readily sharpenable and holds an edge well, it's strongly built and decently sharp from the factory, and the included scabbard is practical and sturdy. For any sort of serious use you'll want a grippier handle, but a fraction of the length of a $2.99 roll of hockey-stick grip tape solved that problem for me.

Here it is on Amazon,

and

here's Hartmann & Haug

,

the people who sell it. At $US49 plus very reasonable delivery, it's a bargain.

Highly recommended.